UPDATE

As you may have heard recently China’s EPA has shut down tens of thousands of factories with no end in sight. Not only are factories being fined for not following the new laws, in some severe cases people are going to jail for this! You can read more about it in this NPR story where they interviewed me.

China Shuts Down Tens Of Thousands Of Factories In Unprecedented Pollution Crackdown

After speaking to other industry experts on the ground in China, here are some important takeaways that I’d like to share with you especially if you have a business that is sourcing products from China.

The good news is that China is cleaning up its manufacturing.

This is positive for both China and the rest of the world. Beijing is known for its legendary levels of pollution. In China, lung cancer rates are climbing astonishingly fast. Also the impact of the pollution can be felt as far away as Japan and even North America! So all in all these stricter environmental regulations are a positive development.

The air seems to be cleaner these days in Shanghai, Shandong, Guangzhou, and Shenzhen. Some have told me that they “can’t remember the last time the skies were so blue!”

Previously it was cheaper for factories to pollute than to cleanup.

In the past the main problem was compliance. Because fines were small and loosely enforced, from a business perspective it was cheaper for a factory to continue operating and paying a small fine than to rehaul their operations and invest in new equipment and processes to cleanup.

But this time the new EPA laws have TEETH.

Local leaders are pressured to force local factories to comply or face stiff fines and penalties. These may include daily fines, cancellation of business licenses, and even criminal enforcement.

What does this mean if you’re sourcing from China?

Unlike before the new laws are here to stay

In the past, these cleanup efforts were temporary due to large socioeconomic and/or political events such as the 2008 Beijing Olympics, 2010 Shanghai World Expo, and 2012 Hangzhou G-20 Economic Summit.

The difference now is that the government leaders have issued direct orders from the top down. We understand that the environmental cleanup is as important as the anti-graft campaigns in China. This is serious stuff folks.

Factories that have been closed may stay closed

I have heard reports of dying mills that have been shut down by the dozen because they cannot comply with the new EPA laws. In other cases factories have been shut down indefinitely.

On the other hand other factories have gone through their audit and passed inspections with a minimal disruption to their operations.

The takeaway is that it depends on your industry, your product, as well as your factory’s operations and level of pollution.

Even if your factory wasn’t affected, their subcontractors may be shut down

One important note is that if your factory wasn’t affected you’re not out of the woods yet. This is because their subcontractors may be affected by the crackdown. This means that if your product is dyed or treated with chemicals – this part of the production process may become a bottleneck that may delay your delivery.

Or some factories may even switch out or even eliminate certain processes altogether.

I’m not necessarily saying that factories are dishonest. But desperate times call for desperate measures and for some factories it’s a fight for survival. It’s not unheard of for factories to forego a certain chemical treatment when that treatment may jeopardize the shipment’s delivery date.

Perhaps more importantly, it boils down to Chinese culture where social harmony is more important that speaking up and causing problems. Often times these problems will be kept to themselves and only brought up when the sh*t hits the fan.

China is moving up the value ladder

On a macro level, China is moving away from the low end and super cheap products that takes a significant toll on its environment. This makes sense as pollution levels have skyrocketed in the past 20 years since China’s economy has boomed.

To put it bluntly, China is willing to let the “dirty” business go to other countries such as India, Bangladesh, and Southeast Asia. At the same time China is focusing on more valuable products whose manufacturing processes depend more on skilled labor and automation. Case in point the Apple iphone.

What can you do? The three C’s

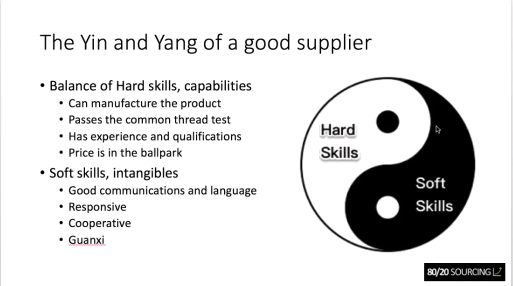

Communicate with your supplier

Remember don’t expect your supplier to give you an advance notice. Remember Chinese culture does not encourage one to make waves. So it’s your job to be proactive in checking with your suppliers if they’re impacted by the new environmental laws.

It’d be smart to check if your delivery schedules are guaranteed as well because you don’t want to miss out on Q4 and the holiday shopping season.

I recommend also asking how long they expect the closures to last so you can plan ahead.

Contingency Plan

Don’t put all your eggs in one basket. It makes sense to have backup suppliers to refer to if your primary supplier goes offline. These can be either other suppliers in China or in other countries.

Contrary to popular belief, not all products are made in China these days. Other countries such as India, Bangladesh, and SE Asia may not be prone to these increased pollution laws.

I recommend also sourcing new suppliers as a long term strategy.

In fact we are in the middle of trade show season right now. I’ve written several articles about how to attend a trade show like a pro. Trade shows are a great way to meet suppliers in person, kick the tires and get your hands on a sample right away so you don’t have to wait for weeks for it to be shipped to you, as well as learn about new product trends and spot new product opportunities.

Change – learn to embrace it

A wise man once said “The only constant thing in business is CHANGE”. So learn to embrace it.

One must adapt quickly or be left behind. If you’re factory is affected it’s up to you to find a supplier that can deliver the right product, at the right price, at the right time.

Short term outlook – Longer lead times

In the short term I expect longer lead times during the shakeout since certain factories are being closed indefinitely.

Long term view – Prices to rise

In the long term, expect prices to rise. Just as California has stricter tailpipe emissions laws which resulted in higher car prices and gas prices, so will China’s stricter environmental laws result in increased costs on suppliers. And these costs will be passed down as price increases onto you the buyer.

It costs more to get clean and expect the price increases to be passed on to you sooner or later.

Moreover raw material prices are rising as well.

But on the bright side, the cost increases will affect everyone equally so you will not be at a disadvantage.

Quick favor

I’m doing an informal survey of businesses who’ve been affected by the China EPA factory closures – Can you take 5 minutes to share with my your insights by filling out this short survey? I’d appreciate it.

Click here to take my 5 min survey

—

A hard stance against “heavy polluters”

If your company is sourcing products from China then there is a major disruption that may be flying under your radar. Since June of 2017, China’s new Ministry of Environment is taking a hard stance against Chinese factories that are “heavy polluters’. In fact in the most recent round of factory audits, China’s environmental crackdown has shut down tens of thousands of Chinese factories with no end in sight.

The effects of decades of massive manufacturing growth has taken its toll on the environment. Now China has some of the most polluted cities in the world. Air purifying equipment and anti-pollution masks sell out often. Groundwater is polluted making safe drinking water a big concern. Now the government is doing something about it.

What’s different this time is that a hard stance is being taken in making sure that factories are compliant with environmental laws. Previously when policies were passed there was little to no compliance. Many factories were unaware or unwilling to comply so they continued operating in their old polluting ways.

Now some factories are being forced to cease their production immediately and indefinitely. And if they don’t comply their power could be shut off leaving them in the dark.

Power trumps Guanxi

And in this case power trumps “guanxi”. Decisions are coming directly from the top levels of government so it overrides any relationships factory owners may have at the municipal levels. If they are noncompliant they will definitely face the consequences if they are audited.

Lack of transparency with no end in sight

One of the issues the factories face is a lack of transparency. Government policy details are quite opaque and many factories are not aware of the exact policies that they must abide by so they may unknowingly continue to operate in noncompliant ways and risk being shut down.

So they face an unpredictable and ongoing risk of being suddenly told to shut down. And there is no clear timeline which means the factories don’t know when or if they can resume production.

So all of this makes it a very challenging time if you are sourcing products from China.

Who’s affected?

According to my research, affected industries include but may not be limited to the following industries.

Affected Industries

- Textiles

- Rubber

- Leather

- Chemicals

- Carbon

- Metal

- Coating

- Plastic

- Dying, Painting, and Printing processes

The environmental audits have been implemented in rollouts that have begun in certain regions mostly centralized in and around Northern China. The later phases will reach other regions. Again it’s difficult to pinpoint exact areas due to lack of transparency.

So far we understand that factories in these regions have been affected

- Shandong

- Henan

- Hebei

- Tianjin

- Beijing

- Zhejiang

- Jilin

- Jiangsu

- Sichuan

- Guandong

Why is the clampdown happening now?

In 2013, China passed the “10 Measures for Environmental Protection” which outlined measures to improve China’s environment. This was monumental as China began addressing admitting the environmental problems head-on while in the past China was more focused on developing its economy with manufacturing while paying a huge expense in air, water, and ground waste pollution. My sources tell me that the newly appointed Minister of Environment is demanding stricter compliance from the factories thus the extensive auditing and review of these tens of thousands of factories.

Moreover if we look at the macro level, China has an important government meeting in the 19th Plenum, the most important government meeting which takes place every five years. Taking place on Oct 18th, 2017, the main objectives are to select the top leaders and policies to put in place as a road map for the country going forward.

Environmental Protection is one of the key issues to be examined. It would make sense to do a bit of cleaning before the meeting to drum up the numbers and also product some blue skies for them to take credit for.

Similar supply chain disruptions in China related to major economic, political, and social events have happened in 2016 in the months preceding the G-20 meetings in Hangzhou as well as in 2008 before the Beijing Olympics.

Other speculators say that another reason is because of a major sporting event and competition at the national level happening in north China in the fall. In my opinion this is a less probable cause than the 19th Plenum which is the most important event that will set the stage for the future of China in the next five years.

What do you do if you are sourcing from China and risk being affected?

If you’re factory has not been affected (yet) then now is the time to check with them to ask if they will be affected.

It’d be smart to ask if their component suppliers are being or will be affected as well.

Note that even if your factories themselves have been audited and approved for production, their component subcontractors may not be so lucky. If their component suppliers get shutdown then your factory will not be able to follow the normal production process and your product may get delayed as they are left scrambling to find a replacement. This makes it more difficult to predict delivery lead times as these external factors may be out of their direct control.

For example if you are manufacturing a mason jar and your glass factory passed inspection but their metal lid subcontractor gets shut down then your factory will have a hard time delivering your product on time as they will need to search for a replacement. Remember you’re only as strong as your weakest link!

Best practice: Be proactive in communicating with your suppliers!

It’s important understand that Chinese culture doesn’t encourage people to reveal bad news until it happens. Often bad news is swept under the carpet until it absolutely has to be revealed. So it pays for you to be proactive to communicate with your supplier and learn about and minimize the disruption to your supply chain.

What if your factories are being affected now?

“Our production scheduling is in total disarray and our suppliers literarily have no idea when they can re-start production.”

Case in point – A friend of mine who has 20+ years experience in China sourcing from a deep base of suppliers is facing a huge headache. He sources from Chinese suppliers who’s products fall under one of the monitored industries and are based in the Shandong province. Even though they are compliant, several of his suppliers have been shut down and they have not received any word about the next steps nor when production can resume. This makes it next to impossible to plan purchase orders for the 4th quarter and pre-Chinese New Year period. His company headquarters is giving him a lot heat for this. What can he do?

Going out of China

One solution is to go out of China. Since my friend’s industry is one of the targeted ones in the new environmental policy regulations, he’s shifting his production to India where their production has not been impacted by environmental policies.

Depending on your industry, some products can be manufactured in other countries such as India, Thailand, Vietnam, etc. This will circumvent the problem until the the disruption passes. Also a general rule of thumb, it’s a good idea to diversify your risk by not putting all your eggs in one basket in China.

In summary, China can be a non-transparent place for doing business. Social-economic and political events can and will affect your business here. So it’s your responsibility to have a backup plan to reduce the impacts of these events on your supply chain. Now would be a good time to talk to your suppliers to find out the extend of the problem and work out solutions. And if you’re facing the impact of these problems head-on, it may be time to consider other countries so you don’t put all your eggs in one basket and have them all break with one sudden jolt.

Have your suppliers been affected by the environmental audits in China? If so, hit reply and let me know what happened and what you’re doing about it.

-Gary